Unlocking Innovation with PA12 in Art Supplies, Product Design & 3D Printing – A Comprehensive Guide

In the dynamic world of modern manufacturing, art, and product development, the importance of advanced materials cannot be overstated. Among the most promising and versatile materials making waves today is PA12, also known as Polyamide 12 or Nylon 12. This durable, flexible, and highly adaptable polymer is revolutionizing sectors from art supplies to product design and 3D printing. At arti90.com, we recognize the value of PA12 in transforming creative processes and manufacturing workflows. In this comprehensive guide, we will explore the multifaceted applications of PA12, its technical advantages, and how it empowers artists, designers, and manufacturers worldwide.

Understanding PA12: The Material that Fuels Innovation

Polyamide 12 (PA12) is a specialized thermoplastic polymer belonging to the nylon family, appreciated for its exceptional chemical resistance, low moisture absorption, and remarkable mechanical properties. Its unique molecular structure, characterized by long aliphatic chains, provides a pantheon of benefits that make it ideal for demanding applications. These include:

- High durability and toughness

- Excellent flexibility even at low temperatures

- Superior chemical resistance to oils, greases, and solvents

- Low moisture absorption that stabilizes dimensional accuracy

- Outstanding printability in additive manufacturing

- Lightweight with high strength-to-weight ratio

The Role of PA12 in Art Supplies: Empowering Creativity and Precision

Artists and art supply manufacturers are increasingly turning to PA12 as a medium that bridges traditional craftsmanship with modern manufacturing. Its flexibility and ease of shaping enable the creation of intricate textures, durable sculptures, and custom tools. For instance, molds and stamps in art projects benefit from PA12's high dimensional stability and resistance to wear, ensuring creations last and maintain their fine details.

Additionally, due to its excellent compatibility with various dyes and paints, PA12 can be colored effectively, allowing artists to imbue their pieces with vibrant hues or subtle shades for nuanced effects. Its low moisture absorption prevents warping or distortion during storage or display, ensuring artworks preserve their integrity over time.

The application of 3D printing with PA12 in art opens up unprecedented possibilities for artists to create bespoke, complex sculptures or functional art pieces quickly and efficiently. It enables *rapid prototyping*, customization, and the forging of innovative artistic expressions previously unattainable with traditional materials.

Revolutionizing Product Design with PA12

The field of product design is constantly evolving, driven by the need for lightweight, durable, and aesthetically pleasing components. PA12 plays a pivotal role in this evolution, serving as a backbone for designers seeking to push the boundaries of innovation. Its versatility allows for the production of prototypes, functional parts, and end-use products that are both cost-effective and reliable.

Advantages of PA12 in Product Design

- Design Flexibility: Enables complex geometries and intricate detailing through advanced manufacturing methods like 3D printing and CNC milling.

- Lightweight Strength: Ideal for applications demanding high strength without excess weight, such as automotive components, consumer electronics, and sports gear.

- Corrosion Resistance: Suitable for outdoor or harsh environment applications, including plumbing parts and marine equipment.

- Cost-Effectiveness: Low manufacturing costs due to ease of fabrication and material efficiency.

Moreover, the compatibility of PA12 with additive manufacturing processes accelerates rapid prototyping and small-batch production, providing designers with a means to iterate rapidly and reduce time-to-market significantly. The *dimensional stability* of PA12 ensures that prototypes accurately reflect final production parts, minimizing costly revisions.

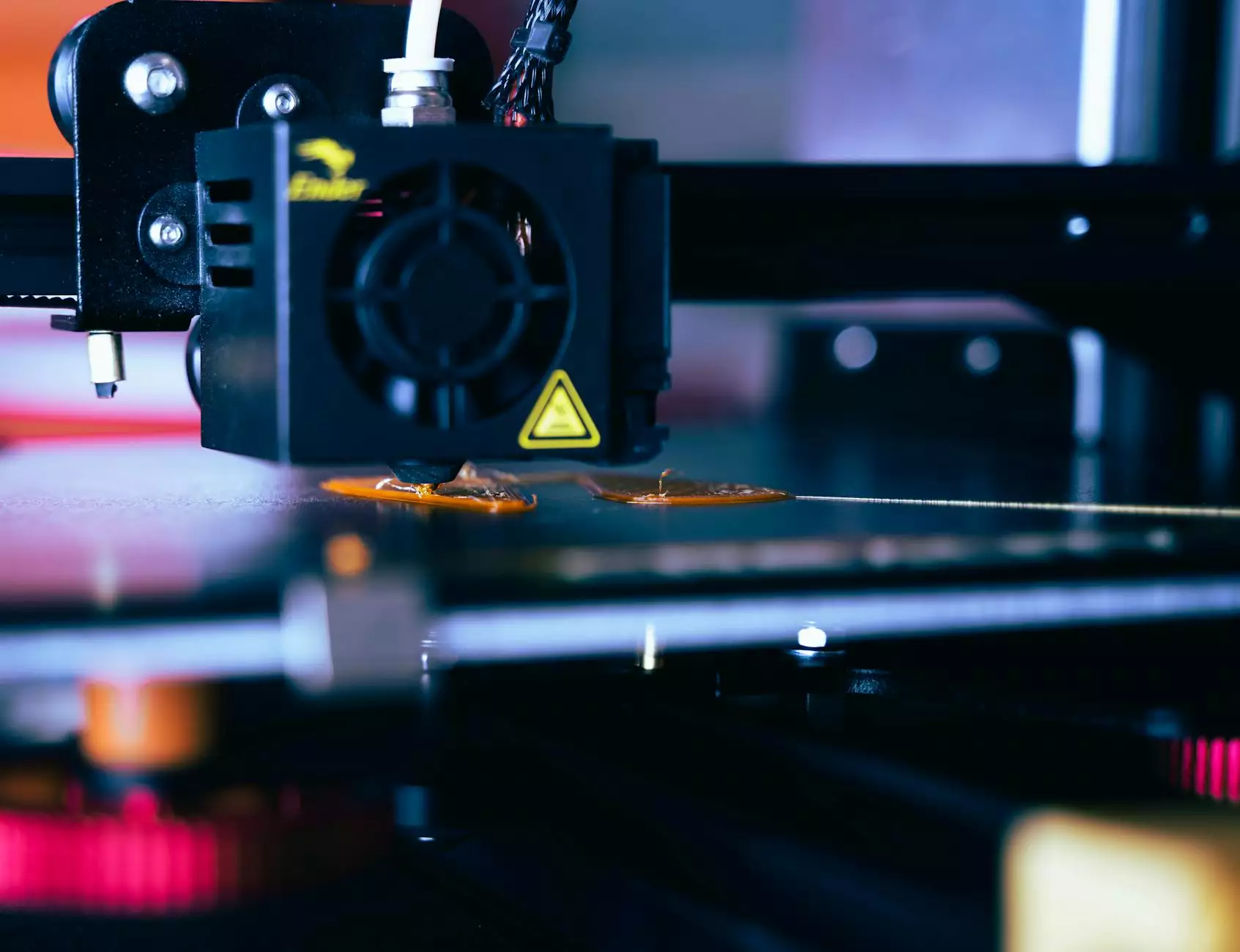

Harnessing PA12 in 3D Printing: A Game Changer

The rise of 3D printing technology has revolutionized how we approach manufacturing, enabling the creation of complex geometries and customized products. Among the various materials available, PA12 stands out as a premier choice for industrial 3D printing applications. Its *mechanical robustness*, combined with ease of processing, makes it ideal for producing functional prototypes, tooling components, and even end-use parts.

Key Benefits of Using PA12 in 3D Printing

- High-Resolution Detail: Ensures precise, intricate designs necessary for functional prototypes and artistic pieces.

- Excellent Mechanical Properties: Provides strength, flexibility, and impact resistance for demanding applications.

- Dimensional Accuracy: Minimizes warping or shrinkage during cooling, ensuring tight tolerances.

- Availability in Various Formulations: Includes flexible, rigid, and colored variants tailored for specific project needs.

- Environmental Resistance: Suitable for parts exposed to oils, fuels, and weather elements.

The ability to produce functional, lightweight, and durable parts rapidly makes PA12-based 3D printing a strategic advantage for industries such as aerospace, automotive, healthcare, and consumer electronics. It allows for on-demand manufacturing, reducing inventory costs and enabling rapid customization.

The Future of PA12 in Creative and Industrial Sectors

As the landscape of art, manufacturing, and product development continues to evolve, the role of PA12 is set to expand even further. Innovations in material science and production technologies are continually improving its properties, making it more adaptable and sustainable. Some key trends shaping the future include:

- Enhanced Sustainability: Development of bio-based and recyclable PA12 variants to meet environmental standards.

- Color and Finish Customization: Advanced dyeing and finishing techniques for aesthetic enhancement.

- Hybrid Material Structures: Combining PA12 with other polymers or composites for multifunctionality.

- Increased Adoption in Medical Devices: Due to its biocompatibility and sterilization capabilities.

Continued research and development promise to unlock even more applications, reinforce sustainability, and promote eco-friendly manufacturing processes. The flexibility, durability, and ease of processing of PA12 position it as a truly game-changing material for the future.

Partnering with arti90.com: Your Source for Premium PA12 Materials and Solutions

At arti90.com, our mission is to empower creators, innovators, and manufacturers with top-quality materials and expert support. We offer an extensive range of PA12 filaments, powders, and sheets tailored for art supplies, product design, and 3D printing.

Whether you're a professional designer seeking precision prototypes, an artist aiming to develop durable sculptures, or an industrial manufacturer looking for reliable parts, our PA12 solutions will meet and exceed your expectations. Our dedicated team provides technical assistance, guidance on best practices, and rapid delivery, ensuring your projects remain on schedule and within budget.

Conclusion: Embrace PA12 for Limitless Possibilities

The versatility and superior properties of PA12 make it a cornerstone material for art, product development, and industry applications. Its capacity to enable complex designs, durable products, and sustainable manufacturing solutions rightfully earns it recognition as an essential material in the modern creative and industrial toolbox.

By integrating PA12 into your workflows and creative projects, you unlock new levels of innovation, achieve cost efficiencies, and craft products with unmatched quality and durability. From art exploration to industrial manufacturing, the future truly belongs to those who leverage the power of advanced materials like PA12.

Explore the possibilities with arti90.com today, and take the first step toward transforming your ideas into reality.